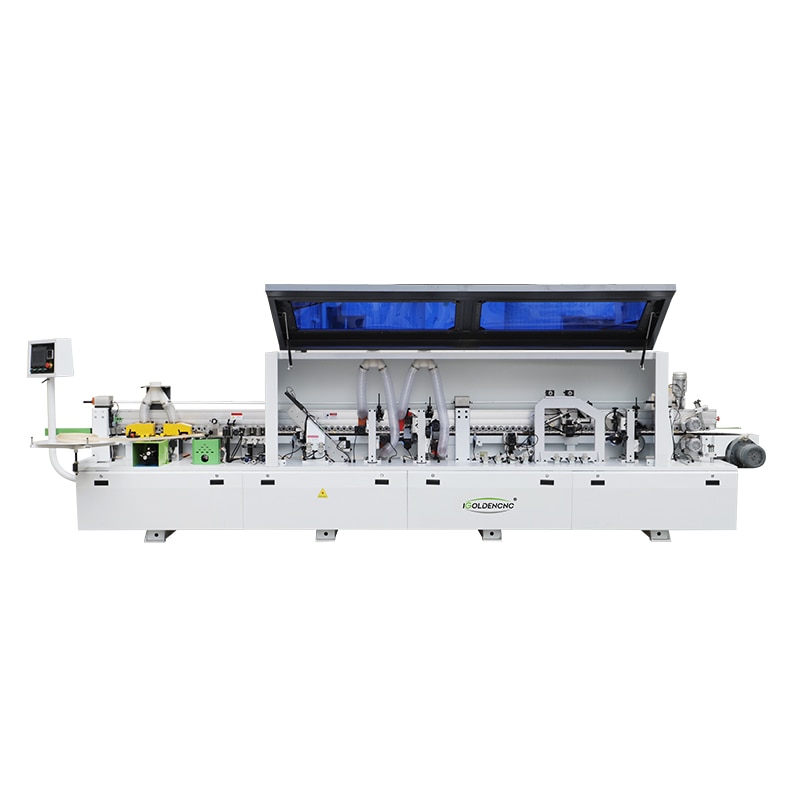

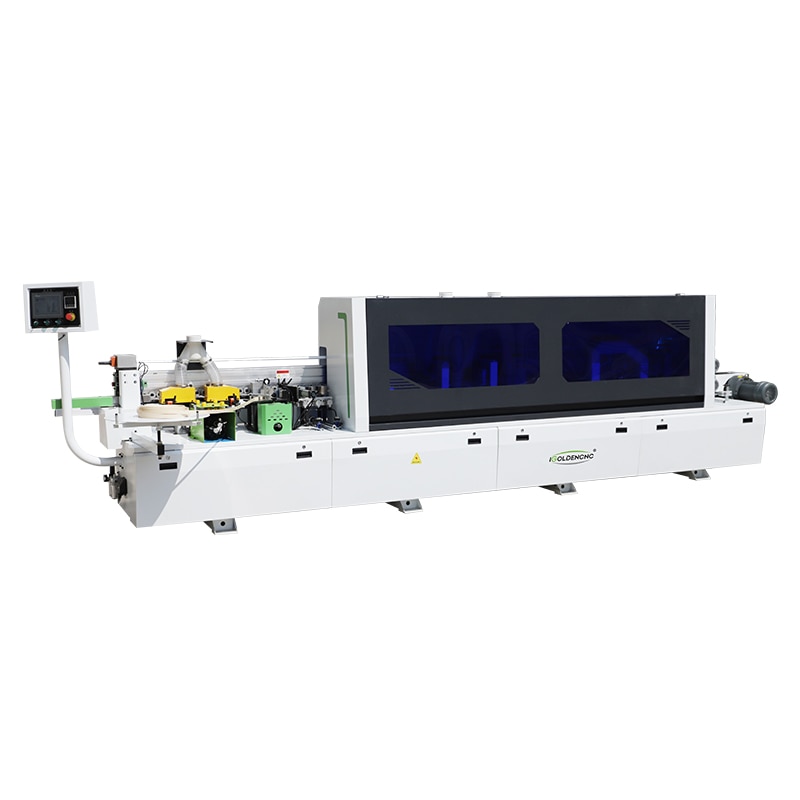

Automatic 8 Function Pvc Edge Banding Machine

$15,900.00

1 in stock

Description

Edge Banding Machine

- Brand Name:?IGOLDENCNC

- Condition:?New

- Certification:?CE

- Place of Origin:?Shandong, China?

- Condition:?New

- Type:?Edge Banding Machine

- Brand Name:?IGOLDENCNC

- Voltage:?380V/50Hz(60HZ)

- Dimension(L*W*H):?6200*900*1600 mm curve edge banding machine

- Power (kW):?edge bander machine

- Weight (KG):?1800 kg

- Warranty:?2 years for cnc edge banding machine

- Function:?Corner Trimming, edge banding

- Key Selling Points:?Sustainable

- Panel Feed Speed(m/min):?22m/min

- Video outgoing-inspection:?Provided

- Warranty of core components:?2 years

- Core Components:?Bearing, Motor, Pump, Gear, PLC, Gearbox, Pressure vessel, Engine

- Product name:?edge banding machine

- Panel thickness:?10-60mm

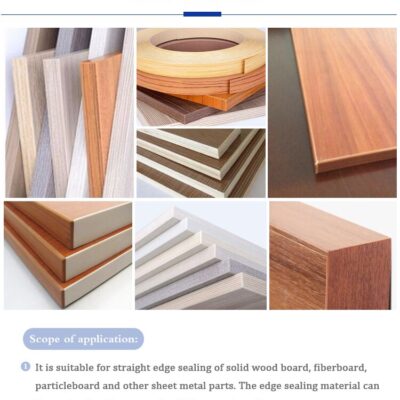

- Application:?Solid Wood Panels

- Usage:?Furniture Panel Edge Banding

- Working methods:?CNC Automatic

- Keywords:?Full-automatic Edge Banding Machine

- Machine function:?Straight Line Banding

- Model:?Mini Automatic Wood Edge Banding Machine

- Steel material:?Hot Press Machine Production Line

- Showroom Location:?Egypt, United States, Malaysia

- Marketing Type:?New Product 2020

- Machinery Test Report:?Provided

Specification

|

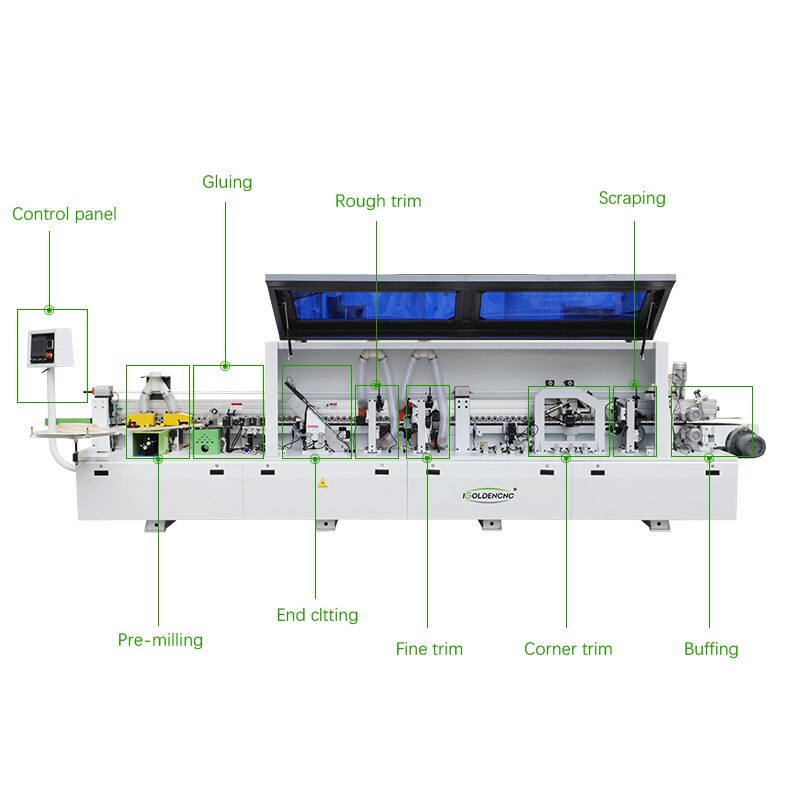

Function

|

Pre-milling?Gluing?

End cutting?Rough trim? Fine trim?Corner trim? Scraping?Buffing |

|

Sheet thickness

|

10-60mm

|

|

Edge material width

|

15-55mm

|

|

Conveyor belt power

|

2.2kw

|

|

Feeding speed

|

15?22m/min

|

|

Total power

|

16.6kw

|

|

Voltage

|

380v

|

|

Dimensions

|

6200*900*1600 mm

|

|

Package dimensions

|

5900*800*1600mm

|

|

Weight

|

1800kg

|

Details Images

The independent LCD

Pre-milling

Gluing

End cutting

Rough trim?

The rough trimming knife is a flat knife, which is used to trim the excess edge banding material on the upper and lower parts of the processed sheet edge band, so that the upper and lower parts of the trimmed sheet are smooth and smooth.

Fine trim?

The finishing knife is an oblique repair, used to repair the excess edge banding material after rough repair on the upper and lower parts of the processed sheet edge band, and at the same time, make the natural transition between the sheet material and the edge band in an arc shape.

The contour is trimmed, and the chamfering effect is repaired, and the edge banding effect is more round and smooth.

Scraping:

It is used to eliminate the ripple marks (cut marks left by the trimming knife and the finishing fillet) caused by the non-linear motion cutting process of the trimming.

Buffing:

Use a cotton polishing wheel to clean the polished plate to remove excess glue and make it smoother.

Samples

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.